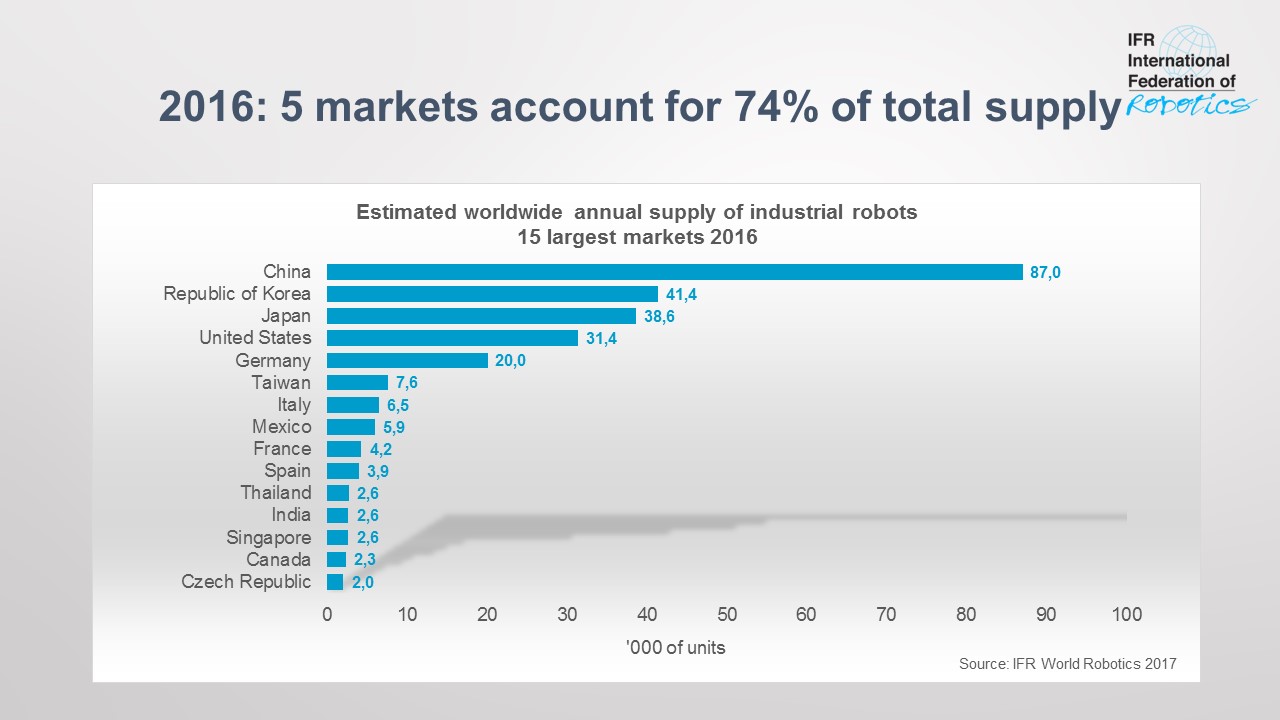

根據IFR, 2016年機器人全球五大市場的產值,佔74%。台灣排名全球第六,緊接於德國之後

IFR News Release

國際機器人聯盟新聞稿 2017.09.27

IFR預測:到2020年將全球工廠改造的新型態機器人將達170萬台

到2020年,全球工廠將安裝170多萬台新型工業機器人

Sep 27, 2017 Frankfurt Today, the strongest growth in the robotics industry is in Asia – lead by China as the world´s number one marketplace. In 2017 robot installations are estimated to increase by 21 percent in the Asia-Australia region. Robot supplies in the Americas will surge by 16 percent and in Europe by 8 percent. Important drivers of this development: robot adoption is a response to faster business cycles and the requirement to produce with greater flexibility tailored to customer demand in all manufacturing sectors. A new generation of industrial robots will pave the way for ever more flexible automation.

2017年9月27日

機器人行業增長最快的是亞洲 – 其中以中國這個現為世界第一的市場領先。在2017年,亞太-澳洲地區的機器人裝置估計增長了21%。美洲地區的機器人供應將增長16%,歐洲增長8%。這一發展的重要推動力是:為因應更快速的商業循環,以及所有製造行業的客戶都要求更大生產彈性與客製化,而採用機器人。新一代工業機器人將為更加靈活的自動化鋪路。

“Robots offer high levels of precision and their connectivity will play a key role in new digital manufacturing environments,” says Joe Gemma, President of the International Federation of Robotics. “Increasing availability enables more and more manufacturers from companies of all sizes to automate.”

國際機器人聯盟主席Joe Gemma表示:“機器人提供高水平的精度,並且,它們之間的連結性將在新數位製造模式中發揮關鍵作用”。 “日益提高的可用性使得越來越多不同規模的製造商走向自動化”。

以下更多新聞內容,請參考IFR官網。

https://ifr.org/ifr-press-releases/

- Industrial robots in operation

- TOP five markets in the world

- Future trend: smart factory

- Future trend: small-to-medium-sized manufacturers to automate

協會摘錄其中要點翻譯如下。

1. 2016年,機器人全球五大市場的產值,佔74%。台灣排名全球第六,緊接於德國之後。

2. 未來趨勢 :

i. 智慧工廠:

工業4.0 - 將現實生活中的工廠與虛擬聯繫起來 - 將在全球製造業中發揮越來越重要的作用。由於系統複雜性和數據不相容性的障礙被克服,製造商可將機器人整合到工廠的機器和系統網絡中。機器人製造商已經在開發和商業化新的服務模式:基於附加在機器人上的傳感器收集即時數據。分析師預測雲端機器人市場迅速增長,特別是將來自一個機器人的數據與來自相同或不同位置的其他機器人的數據進行比較。雲端網絡允許這些連接的機器人執行相同的活動。這將用於優化機器人運動的參數,如速度,角度或力。最終,製造業大數據的出現可能會重新定義設備製造商和製造商之界線。

Industry 4.0 - linking the real-life factory with virtual reality - will play an increasingly important role in global manufacturing. As obstacles like system complexities and data incompatibility are overcome, manufacturers will integrate robots into factory-wide networks of machines and systems. Robot manufacturers are already developing and commercializing new service models: these are based on real-time data collected by sensors which are attached to robots. Analysts predict a rapidly growing market for cloud robotics in which data from one robot is compared to data from other robots in the same or different locations. The cloud network allows these connected robots to perform the same activities. This will be used to optimize parameters of the robot’s movement such as speed, angle or force. Ultimately, the advent of big data in manufacturing could redefine the industry boundaries between equipment makers and manufacturers.

ii. 中小規模製造廠走向自動化:

一些機器人製造商也在考慮租賃模式,特別是為了加速中小型製造商的採用。簡化是這個區段市場的關鍵趨勢。對於更易於使用和編程的機器人的持續需求以及越來越多的靈活自動化的需求日益增加,開始開發更智能的解決方案。這對於內部缺乏專屬的製程設計工程師的行業尤其有幫助。因此,重要的是提供易於使用的機器人,其可以容易地應用到標準生產過程中。使用不複雜的機器人將能夠在許多行業部署工業機器人,以維持高效靈活的製造。

Some robot manufacturers are also considering leasing models, particularly in order to accelerate adoption by small-to-medium-sized manufacturers. Simplification is a key trend for this market segment. The ongoing need for robots which are easier to use and to program and the increasing need for ever more flexible automation initiated the development of smarter solutions. This is especially useful for industries with a lack of specialized production engineers in-house. Thus, it is important to provide easy-to-use robots that can easily be integrated into and operated in standard production processes. Robots that are uncomplicated to use will enable the deployment of industrial robots in many industries to sustain efficient and flexible manufacturing.

取材自:IFR news release

(2017/9/27)